Super Purchasing for 9 1/2 Inch 7 Blades Pdc Bit - Matrix pdc bit M1975 – Ruishi

Super Purchasing for 9 1/2 Inch 7 Blades Pdc Bit - Matrix pdc bit M1975 – Ruishi Detail:

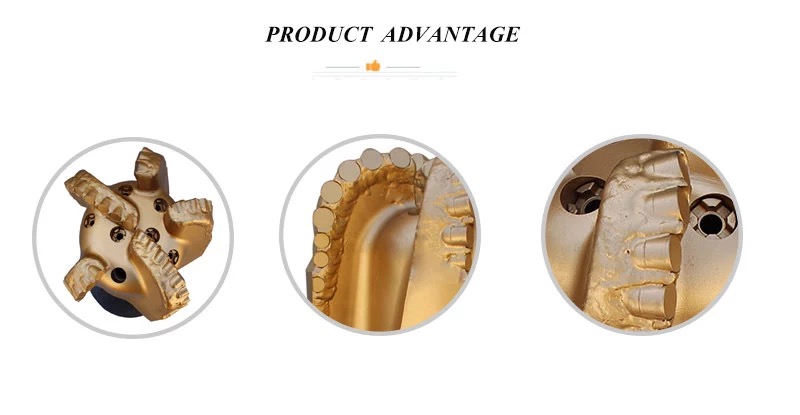

PDC BITS are equipped with Hardened Alloy Steel base material;High performance PDC-Cutters;Carbide and Diamond gauge protection;Carbide/Diamond Shock Studs;Threaded or Plain Carbide Nozzles for Flushing.Above features are subject to changes and modifications according to customers’ requirements.

The Diamond PDC bit designed to run at high penetration rates even in applications that call for higher blade and cutter counts. Its unique cutting structure layout adds another dimension to bit stability and smooth running by combining the penetration rate potential of traditional “single set” cutter layouts with the life extending features of a “plural set” cutter layout. The result is a bit that runs up to 20 percent faster than conventional PDC bits with minimum bit wear.

1、Single row spiral seven blades design, significantly increases wear resistance and stability of the bit.

2、Extended gauge ensures the bit is maintained for a long period of time,increases the steady resistance to pressure of the bit.

3、Limiting cutter in inner cone design, lessens bit torque and improves steerability in directional drilling.

Features:

1、Deep blade and long parabolic configuration design, ensures optimal bottom hole flow pattern and anti-balling.

2、Optimize the cutting structure and places high quality cutters at different points, increases wear resistance and offensive of the bit .

3、Anti-whirl design improves ROP and enhances the drilling stability.

4、Manufactured with high quality tungsten carbide matrix powder, ensures erosion resistance of the bit.

Application: Suitable for soft to medium hard formation, such as shale, sandstone, chalk rock, etc.

|

Bit |

SPECCIFICATIONS |

RECOMMENDED PARAMETERS |

||||||

|

Size |

Number of Blade |

Primary Cutter Size |

Nozzle Qty |

Gauge Length |

Connection |

Rotary Speed (rpm) |

Weight On Bit (KN) |

Flow Rate (lps) |

|

12-1/4” |

7 |

19mm |

7 |

2’’~3.5’’ |

6-5/8’’API REG |

60~250 |

20~110 |

40~55 |

Product detail pictures:

Related Product Guide:

Dependable good quality and very good credit score standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of "quality initial, shopper supreme" for Super Purchasing for 9 1/2 Inch 7 Blades Pdc Bit - Matrix pdc bit M1975 – Ruishi , The product will supply to all over the world, such as: Kuwait, Greece, Latvia, Our company's main products are widely used all over the world; 80% of our products exported to the United States, Japan, Europe and other markets. All stuff sincerely welcome guests come to visit our factory.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.