Steel Body PDC Bit S1385FG-8-12

PDC drill bit with deep blade and long parabolic configuration, ensure optimal bottom hole flow pattern and anti-balling.

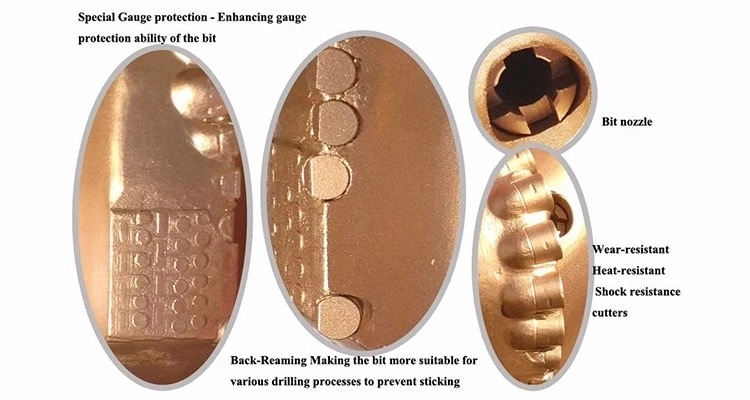

Arc blade and spiral gauge enhance the cutting capability and the drilling stabilization.

Medial cutter density design is suitable for soft to medial formations.

1、Double rows eight blades design, significantly increases wear resistance and stability of the bit.

2、Extended gauge ensures the bit is maintained for a long period of time,increases the steady resistance to pressure of the bit.

3、The surface of the blade is welded by wear-resistant hardfacing material, improves wear resistance and erosion resistance of the bit.

Features:

1、Deep blade and short parabolic configuration design,ensures optimal bottom hole flow pattern and anti-balling.

2、Optimize the cutting structure and places high quality cutters at different points, increases wear resistance and offensive of the bit .

3、Anti-whirl design improves ROP and enhances drilling stability.

Application: Suitable for hard formation with high compressive strength and abrasiveness, such as limestone, hard gypsum, dolomite and sandstone, etc.

|

Bit |

SPECCIFICATIONS |

RECOMMENDED PARAMETERS |

||||||

|

Size |

Number of Blade |

Primary Cutter Size |

Nozzle Qty |

Gauge Length |

Connection |

Rotary Speed (rpm) |

Weight On Bit (KN) |

Flow Rate (lps) |

|

8-1/2” |

8 |

13mm |

7 |

2’’~3.5’’ |

4-1/2’’API REG |

60~250 |

10~100 |

25~36 |

Matters need attention for use of the tricone bit:

1. Before the bit goes down the well, it is necessary to confirm that the bottom hole is clean.

2. Check whether the thread connection and the nozzle installation are intact.

3.Drilling should be smooth and avoid excessive pressure and rough drilling.

4. The last single root shall start the rotary table with large displacement, and drill the hole to the bottom of the well to fully wash the well and prevent cuttings from blocking the nozzle.

5. When creating the shape of the bottom hole, the bottom hole should be touched steadily with low bit pressure, low rotation speed, large displacement, and low torque. The rotation speed should be 40-60r/min for at least 30 minutes.

6. The reasonable determination of bit weight and rotation speed should refer to the parameters recommended in the bit operating instructions and combine with the actual situation of the formation.

7. During drilling, the operation should be smooth and the drilling delivery should be even. It is strictly prohibited to lift and release sharply, slide and stop drilling.

8. If the drill bit has no footage, the pump pressure increases or decreases obviously, the mechanical drilling speed suddenly decreases, the torque increases and other phenomena, the drilling shall be pooh and checked.