Reliable Supplier Milled Tooth Drill Bit - Matrix pdc bit M1975 – Ruishi

Reliable Supplier Milled Tooth Drill Bit - Matrix pdc bit M1975 – Ruishi Detail:

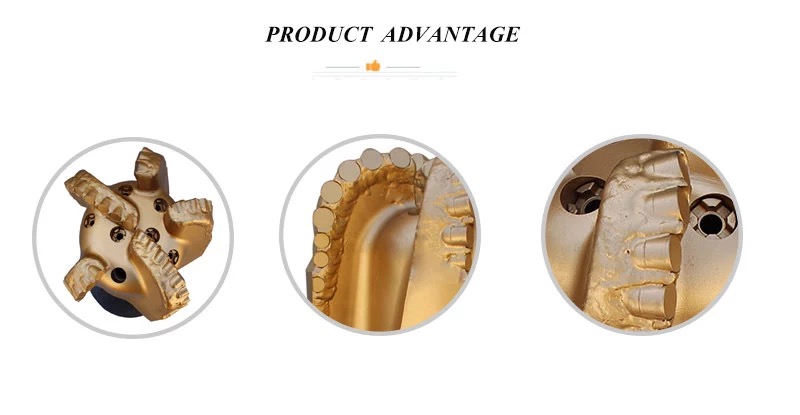

PDC BITS are equipped with Hardened Alloy Steel base material;High performance PDC-Cutters;Carbide and Diamond gauge protection;Carbide/Diamond Shock Studs;Threaded or Plain Carbide Nozzles for Flushing.Above features are subject to changes and modifications according to customers’ requirements.

The Diamond PDC bit designed to run at high penetration rates even in applications that call for higher blade and cutter counts. Its unique cutting structure layout adds another dimension to bit stability and smooth running by combining the penetration rate potential of traditional “single set” cutter layouts with the life extending features of a “plural set” cutter layout. The result is a bit that runs up to 20 percent faster than conventional PDC bits with minimum bit wear.

1、Single row spiral seven blades design, significantly increases wear resistance and stability of the bit.

2、Extended gauge ensures the bit is maintained for a long period of time,increases the steady resistance to pressure of the bit.

3、Limiting cutter in inner cone design, lessens bit torque and improves steerability in directional drilling.

Features:

1、Deep blade and long parabolic configuration design, ensures optimal bottom hole flow pattern and anti-balling.

2、Optimize the cutting structure and places high quality cutters at different points, increases wear resistance and offensive of the bit .

3、Anti-whirl design improves ROP and enhances the drilling stability.

4、Manufactured with high quality tungsten carbide matrix powder, ensures erosion resistance of the bit.

Application: Suitable for soft to medium hard formation, such as shale, sandstone, chalk rock, etc.

|

Bit |

SPECCIFICATIONS |

RECOMMENDED PARAMETERS |

||||||

|

Size |

Number of Blade |

Primary Cutter Size |

Nozzle Qty |

Gauge Length |

Connection |

Rotary Speed (rpm) |

Weight On Bit (KN) |

Flow Rate (lps) |

|

12-1/4” |

7 |

19mm |

7 |

2’’~3.5’’ |

6-5/8’’API REG |

60~250 |

20~110 |

40~55 |

Product detail pictures:

Related Product Guide:

The key to our success is "Good Product Quality, Reasonable Value and Efficient Service" for Reliable Supplier Milled Tooth Drill Bit - Matrix pdc bit M1975 – Ruishi , The product will supply to all over the world, such as: kazakhstan, Melbourne, Iran, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We are looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.